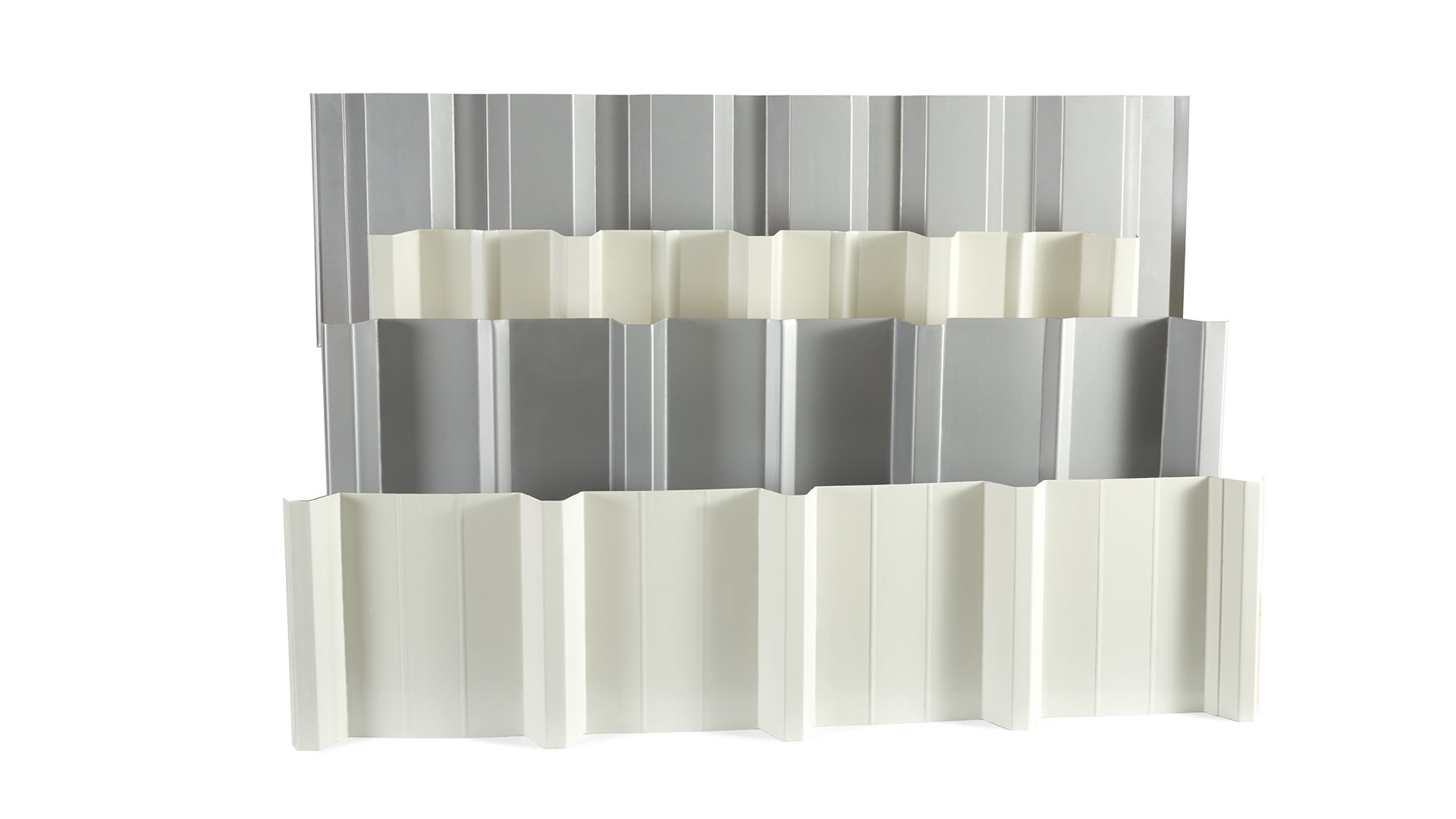

ÇK 90 Corrugated Roof Sheet

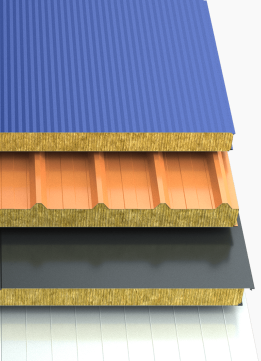

They are corrugated roof sheets manufactured for structures with no insulation needs and for the insulation system with on-site installation.

BrochureTechnical Informations

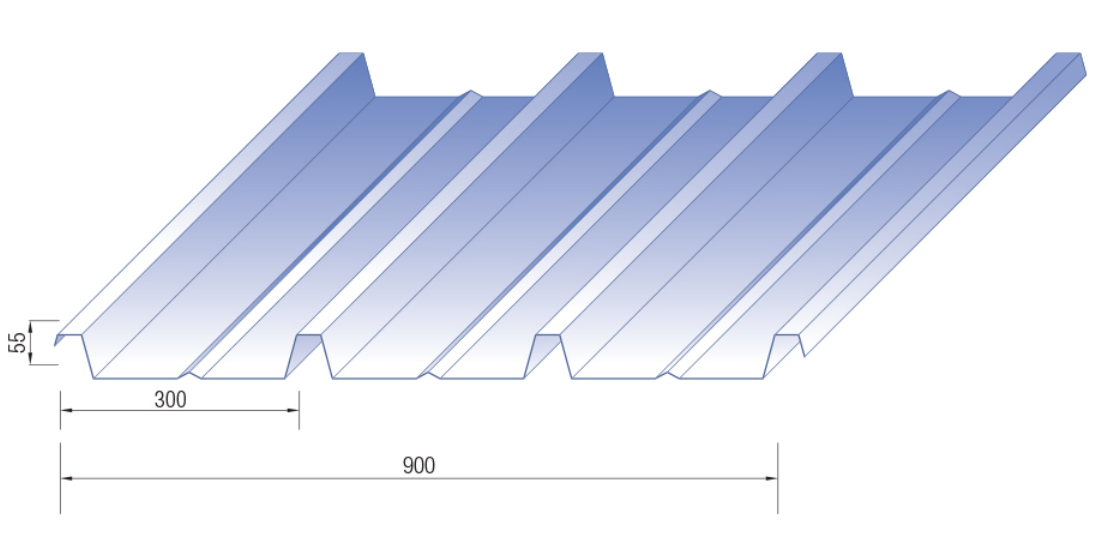

Technical Features

| Product Name | ÇK 90 | ||||

| Useful Width (mm) | 900 | ||||

| Rib Height (mm) | 55 | ||||

|

Thickness (mm) |

0,50 - 1,20 | ||||

| Paint Type | Polyester,PVdF | ||||

| Color | RAL 9002a | ||||

Carrying Table

| ÇK 90 | Multi Support Span (L/200 L=m) | |||||||

| Sheet Thickness (mm) | Corrugated Weight (kg/m2) | 1,0 | 1,5 | 2,0 | 2,5 | 3,0 | 3,5 | 4,0 |

| Distributed Load Bearing (P=kg/m2) | ||||||||

| 0,5 | 5,32 | 813 | 361 | 203 | 130 | 90 | 66 | 47 |

| 0,6 | 6,38 | 995 | 442 | 249 | 159 | 111 | 81 | 59 |

| 0,7 | 7,45 | 1179 | 524 | 295 | 189 | 131 | 96 | 71 |

| 0,8 | 8,51 | 1366 | 607 | 342 | 219 | 152 | 112 | 84 |

| 0,9 | 9,58 | 1556 | 691 | 389 | 249 | 173 | 127 | 97 |

| 1,0 | 10,64 | 1745 | 775 | 436 | 279 | 194 | 142 | 109 |

| 1,2 | 12,77 | 2125 | 944 | 531 | 340 | 236 | 173 | 133 |

Certificates and Documents

Scope Of Application

Scope Of Application

Factories, industrial facilities, shopping malls, gyms, airports, large-scale buildings, residential buildings, chicken farms, workshops, storages, warehouses, prefabricated structures, containers,

Panel Joint Detail

Frequently Asked Questions

Where Can I Buy / Find Izocam Tekiz Products ?

Izocam Tekiz Products are available at İZOCAM-TEKİZ dealers. We do not offer direct sales.

Who Install Izocam Tekiz Products ?

Product installations are handled by İZOCAM-TEKİZ Installation Dealers.

Are Izocam Tekiz Products Kept In Stock ?

Products are produced to order. They are not kept in stock. İzofom Panels are kept in stock by retail sales dealers.

What Is The Warranty Term Of Izocam Tekiz Products ?

The warranty term is 2 years.

What Should Insulation Thickness Be Based Off Of ?

TS825 separates our country into 4 Regions. The Insulation Thickness should be calculated based on the required value of Uceiling and Uwall (Heat Permeability Coefficient).

What Should Sheet Thicknesses Be Based Off Of ?

Tekiz website and catalogues show the spring load-bearing capacity for each span. You may use this table to determine the appropriate sheet thickness.

Are All Colours Listed In Ral (Classic) Catalogue Available For Production ?

All colours in the RAL Catalogue are available for production provided that a minimum limit is exceeded. The standard sandwich panel/corrugated sheet colour is RAL9002.

Why Should Stone Wool Insulated Sandwich Panel Be The Prefferred Choice ?

Stone wool panels feature high fire resistance. They minimise insurance premiums. They safeguard your investment and prevent the fire from spreading, ensuring safety of your employees at high-risk facilities.

What Is Rei120?

Fire resistance duration for roof sandwich panels. It means that the sandwich panel can bear load, preserve its integrity and maintain its insulation properties for 120 minutes. The important matter to note here is the availability of these three properties (REI120) concurrently.

R : Load-bearing capacity

E : Integrity

I : Insulation

What Is The Flammability Class Of Sandwich Panels ?

The Regulation on Fire-Proofing Buildings categorise the flammability classes of building materials in line with the fire-reaction classification established with EN 13501-1 Euroclass.

The flammability classes of building materials are A1, A2, B, C, D, E and F.

Smoke and drip classes of the materials are not provided for the classes A1 and F.

Smoke and drip classes of the materials are always provided for the classes A2, B, C and D. For instance: A2-s1,d0 or C-s3,d2.

What Is The Broof (T2) Certification?

The term Broof roof plating, which meets all criteria for “External Fire Performance” without running any tests, is used to define the product that makes up the uppermost layer in the roof composition.

There is no need for Broof to be tested for panels where both surfaces are metal.

İzocam-Tekiz Kombi panel and PIR Fibro panel bear the Broof(t2) certification, which means they are resistant to external spread of fire. The (t2) annotation here means that tests were performed in windy conditions.

What Is Ei60?

Fire resistance duration for facade sandwich panels. It means that the sandwich panel preserve

its integrity and maintain its insulation properties for 60 minutes. The important matter to note here is

the availability of these two properties (EI60) concurrently.

E → Integrity

I → Insulation